Fiber Lasers Machinery 6 Bench Grinder

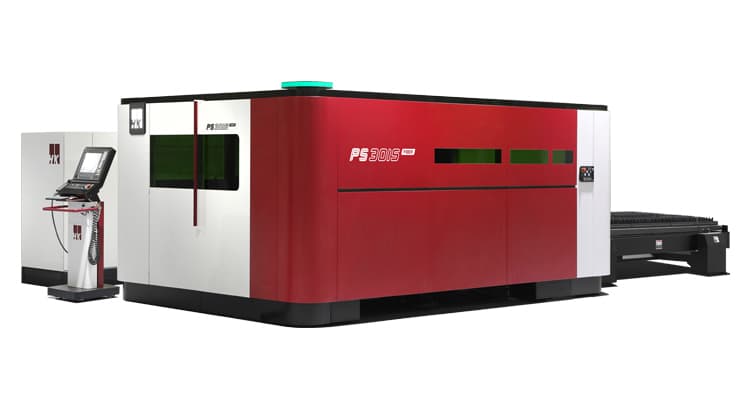

This fiber laser can give a repetitive precision of �0.0001" with a beam quality of less than 1.1 M2.

For advanced designing, you can use other CAD programs (like Photoshop, AutoCAD, CorelDRAW) and import files into EZCAD2.0 in JPG, DXF, PNG, PLT, PCX, DXF, and BMP file formats.